When it comes to HVAC systems, ductwork is a crucial component that allows for proper ventilation and air distribution throughout a home or building. Two common types of ductwork are fabric and metal ducts, each with its own unique features and benefits.

Finding the right ductwork helps maximize your operation’s efficiency and investment. When looking for the right ductwork for your facility, it’s essential to understand the difference between metal and fabric ductwork so you can find the best option. Metal ductwork is famous for its durability and extended life span, while fabric can act as a more budget-friendly choice. Let’s explore the differences between fabric and metal ductwork to ensure you get a lasting, effective product.

Pros and Cons of Fabric Ductwork

Fabric ductwork — also known as air socks or textile ducts — is made of porous, lightweight fabric that diffuses air through small perforations. Fabric duct offers several advantages over metal duct, including:

- Cost-effectiveness: Fabric ductwork’s cost is typically less than metal ductwork in terms of material and installation expenses. This fact makes it an attractive option for budget-conscious projects.

- Customizability: You can customize fabric ductwork to fit any space or design with options for different colors, shapes and sizes. Greater flexibility allows for more design freedom and aesthetic appeal.

- Ease of installation: Fabric ductwork is lightweight and easy to install, requiring fewer tools and labor than metal ductwork. As a result, you can enjoy reduced installation time and costs.

- Energy efficiency: Fabric ductwork can help improve energy efficiency by distributing air more evenly and reducing pressure drops. This can lead to lower energy bills and a more comfortable indoor environment.

Fabric ductwork has a few potential disadvantages, such as:

- Less durability: Fabric is less durable than metal and can be more prone to damage from moisture, UV exposure, and wear and tear. This can result in more frequent maintenance and replacement costs.

- Less fire resistance: Fabric ductwork may be less fire-resistant than metal ductwork, potentially spreading flames more quickly in the event of a fire. This can be a safety concern in certain applications.

- More susceptible to pests: Fabric ducts can be more susceptible to insect and rodent intrusion compared to metal ductwork. With improper sealing and maintenance, there’s a risk your ducts will become compromised by these creatures.

Overall, fabric ductwork can be a cost-effective and customizable option for HVAC systems, but you’ll want to weigh the potential benefits and drawbacks before deciding.

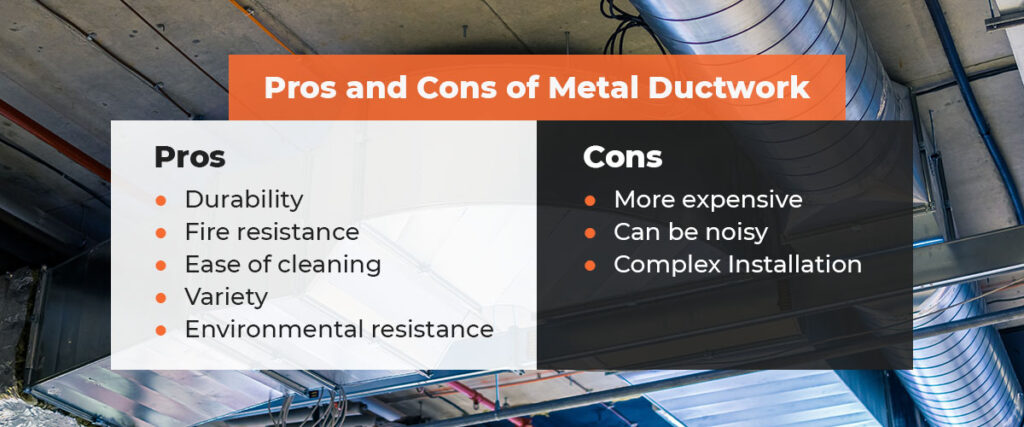

Pros and Cons of Metal Ductwork

Metal ductwork is made of various types of metal, such as galvanized steel, aluminum or stainless steel. The ducts are typically rectangular or circular. Here are the advantages of using metal ductwork in HVAC systems:

- Durability: Metal ductwork is known for its durability and can last for decades without needing replacement.

- Fire resistance: Metal is fire-resistant, helping to slow or prevent the spread of fire in an emergency.

- Ease of cleaning: Sheet metal requires minimal care and is easy to clean.

- Variety: Metal ductwork comes in more options than just round, unlike fabric ductwork. Spiral metal ductwork helps reduce friction, making your ducts more energy-efficient.

- Environmental resistance: Metal ductwork is resistant to more than just fire. Metal ducts are suitable for a wide range of environmental conditions, including extreme temperatures, exposure to moisture and corrosive environments.

Metal ductwork has a few disadvantages to consider, such as:

- Cost: Metal ductwork is generally more expensive than fabric options.

- Noise: This type of ductwork can be noisy, especially without proper installation or insulation.

- Installation: Installing metal ductwork can be more complex due to its weight and the need for accessories like hanger brackets and air valves, which can drive up installation costs.

Metal ductwork is a durable, fire-resistant option that’s suitable for a range of applications. While it’s more expensive to install, you’ll save on replacement costs compared to fabric. If you’re looking for strong, lasting ductwork that can handle high-pressure systems, metal ductwork might be the right option for your facility.

Comparing the Costs and Features of Fabric Ductwork vs. Metal Ductwork

Now that you know the pros and cons of each type of ductwork, let’s compare the costs and features to help you choose between the two. Remember to weigh your needs and long-term goals against the features of these two materials to ensure you get the right type.

Costs

Fabric ductwork is generally less expensive than metal. It requires less material and labor to install, making it a cost-effective option for many building owners and contractors. On the other hand, metal ductwork is more expensive due to the cost of materials and the labor needed for installation. Overall, metal options are more durable than fabric and can last decades without replacement, offsetting the higher upfront cost.

Request a Custom Ductwork Quote

Features

Fabric ducting systems are lightweight and easy to install, making them a popular material choice for retrofit projects and temporary installations. Fabric is also flexible and can be designed to fit a building or space’s specific needs. This type of ductwork typically consists of polyester or other synthetic materials and can be designed for aesthetic value, with various colors and patterns available.

Metal ductwork is more durable and longer-lasting than fabric. It can improve indoor air quality because metal is less likely to foster mold growth. At the same time, metal duct can be noisy and requires regular maintenance to prevent condensation. Its ability to withstand more severe environmental conditions than fabric makes it ideal for demanding operations.

Overall, fabric ductwork is a cost-effective and flexible option particularly suitable for large commercial and manufacturing facilities thanks to its high efficiency. While metal ductwork is more expensive upfront, you’ll save in the long run with its durability and fire-resistance. Fabric ductwork must be replaced more frequently than metal ductwork since the material wears out. Fabric can be a good option for your operation, but metal offers better environmental resistance, enhanced durability and reduced maintenance.

With quality metal ductwork, you’ll reduce long-term costs and enjoy clean air for years to come.

Hennemuth Metal Fabricators Is Your Source for Custom Metal Ducts

If you’re looking for lasting, reliable duct products, Hennemuth Metal Fabricators has the expertise and the quality you need. We provide custom ducts and various fittings for HVAC contractors. Whether for a residential space or a commercial facility, our experienced team can design and fabricate ducts that deliver optimal durability and performance in Pittsburgh, PA and beyond. We take pride in delivering ductwork solutions that stand the test of time.

Don’t compromise on quality — reach out to us today to learn more about our products and services or request a quote for commercial projects. We look forward to working with you!